US NAVY SCUBA DIVING & UNDERWATER WELDING MANUALs 1200pgs gas arc weld & salvage

Item Description

Item Details

Item Description

1970 70 1971 71 mopar dodge chrysler imperial

THE U.S. NAVY DIVING MANUAL

AND

THE U.S. NAVY UNDERWATER WELDING MANUAL

Nearly 1200 PAGES OF DIVING DIAGRAMS AND DATA! Don't confuse this manual with smaller ones...This one is the COMPLETE 1200 page version !

This Covers nearly ALL aspects of Recreational and Commercial Diving and offers a wealth of information from the true Pros of the Business

The U.S. Navy Diving Manual CD contains all 5 volumes covering Scuba, Air, Mixed Gas, Re-Breathers, Chamber Operations, Equipment, Dive Medicine, and all the Decompression Tables.

- Vol. 1: Diving Principles and Policies

- Vol. 2: Air Diving Operations

- Vol. 3: Mixed-Gas Surface-Supplied Diving Operations

- Vol. 4: Closed-Circuit and Semi-closed Circuit Diving Operations

- Vol. 5: Diving Medicine & Recompression Chamber Operations

* WE SHIP WORLDWIDE TO: ENGLAND, SWEDEN, DENMARK, THE NETHERLANDS, CANADA, AUSTRALIA AND ALL OF EUROPE ! (see shipping rates below)

THE

U.S. Navy Underwater Welding and Cutting Manual

This CD contains:

TABLE OF CONTENTS

FOREWARD....................................................................................................................... i

TABLE OF CONTENTS................................................................................................... iii

LIST OF ILLUSTRATIONS............................................................................................. ixv

LIST OF TABLES............................................................................................................. xi

STANDARD NAVY SYNTAX SUMMARY ................................................................ xiii

SAFETY SUMMARY.......................................................................................................xvvv

CHAPTER (1).......... INTRODUCTION

1-1 SCOPE........................................................................................................... 1-1

1-2 UNDERWATER CUTTING OVERVIEW................................................... 1-1

1-3 UNDERWATER WELDING OVERVIEW ................................................. 1-2

CHAPTER (2)..........UNDERWATER CUTTING

2-1 INTRODUCTION ......................................................................................... 2-1

2-2 OXYGEN-ARC CUTTING .......................................................................... 2-2

2-2.1 Principles of Operation .................................................................................. 2-2

2-2.2 Steel-Tubular Electrodes................................................................................ 2-2

2-2.2.1 Advantages of the Steel-Tubular Electrodes ................................................. 2-5

2-2.2.2 Disadvantages of the Steel-Tubular Electrode............................................... 2-5

2-2.3 Electrode Amperage Requirements ............................................................... 2-5

2-2.4 Oxygen Requirements.................................................................................... 2-6

2-2.5 Material Consumption ................................................................................... 2-6

2-2.6 Oxygen Pressure ............................................................................................ 2-6

2-2.7 Oxygen Purity .............................................................................................. 2-11

2-2.8 Grounding the Work .................................................................................... 2-11

2-2.9 Steel-Tubular Electrode Cutting Technique (Thick plate) .......................... 2-11

2-2.10 Steel-Tubular Electrode Cutting Technique (Thin plate) ............................ 2-15

2-2.11 Piercing Holes in Steel Plate........................................................................ 2-15

2-2.12 Steel-Tubular Electrode Cutting Technique (Cast Iron and Non-Ferrous Metals) ......................................................................................................... 2-18

2-2.13 Post-dive Maintenance................................................................................. 2-18

2-3 EXOTHERMIC ELECTRODES................................................................. 2-22

2-3.1 Electrode Amperage Requirements ............................................................. 2-22

2-3.2 Oxygen Requirements.................................................................................. 2-25

2-3.3 Material Consumption ................................................................................. 2-25

2-3.4 Advantages and Disadvantages of the Exothermic Electrode Cutting Process ......................................................................................................... 2-25

2-3.4.1 Disadvantages of Exothermic Electrodes .................................................... 2-27

2-3.5 Grounding the Work .................................................................................... 2-27

2-3.6 Exothermic Cutting Technique .................................................................... 2-28

2-3.6.1 Exothermic Cutting Technique (Cast Iron, Stainless Steel and Non-Ferrous Metals).................................................................................... 2-30

2-3.6.2 Exothermic Cutting Technique (Concrete, Rock and other Non-Conductive Materials) ......................................................................... 2-31

2-3.6.3 Exothermic Hole Piercing............................................................................ 2-31

2-3.7 Trouble Shooting.......................................................................................... 2-31

2-3.7.1 Symptoms .................................................................................................... 2-31

2-3.7.2 Probable Causes........................................................................................... 2-32

2-3.7.3 Locating and Solving the Problem............................................................... 2-32

2-3.8 Post-Dive Maintenance................................................................................ 2-33

2-4 SEELER ENTERPRISES LU-001 EXOTHERMIC CUTTING TOOL (KERIE CABLE)........................................................... 2-33

2-4.1 Advantages and Disadvantages of the of the Kerie Cable........................... 2-34

2-4.2 Materials Required for Kerie Cable Cutting................................................ 2-35

2-4.3 Equipment Set-up ........................................................................................ 2-37

2-4.4 Kerie Cable Preparation............................................................................... 2-39

2-4.5 Cutting Underwater...................................................................................... 2-39

2-4.6 Cutting Technique........................................................................................ 2-40

2-4.7 Cutting Thin Metals ..................................................................................... 2-40

2-4.8 Cutting Thick Metals ................................................................................... 2-41

2-4.9 Re-Lighting Cable Underwater.................................................................... 2-43

2-4.10 Emergency Off Safety Procedures............................................................... 2-43

2-4.11 Loss of Communications ............................................................................. 2-43

2-4.12 Equipment Tender........................................................................................ 2-43

2-4.13 Electrical Precautions .................................................................................. 2-43

2-4.14 Post-Dive Maintenance................................................................................ 2-43

2-5 SHIELDED METAL ARC CUTTING........................................................ 2-44

2-5.1 Principles of Operation ................................................................................ 2-44

2-5.2 Materials ...................................................................................................... 2-44

2-5.3 Waterproofing Electrodes ............................................................................ 2-44

2-5.4 Underwater Shielded Metal-Arc Cutting Techniques.................................. 2-45

2-5.5 Drag Technique............................................................................................ 2-46

2-6 CONCLUSION............................................................................................ 2-46

CHAPTER (3).......... UNDERWATER WELDING

3-1 INTRODUCTION ......................................................................................... 3-1

3-2 MECHANICAL BARRIERS ........................................................................ 3-2

3-2.1 Cofferdams and Caissons............................................................................... 3-2

3-2.2 Mini-Habitats ................................................................................................. 3-2

3-3 SHIELDED METAL-ARC WELDING ........................................................ 3-3

3-4 WET WELDING ........................................................................................... 3-3

3-5 SHIPBUILDING MATERIALS.................................................................... 3-3

3-6 MATERIALS USED IN UNDERWATER SHIELDED METAL-ARC WELDING..................................................................................................... 3-6

3-6.1 Underwater Shielded Metal-Arc Welding Electrodes ................................... 3-6

3-6.2 Tong Test Ammeter ....................................................................................... 3-6

3-6.3 Electrode Polarity .......................................................................................... 3-6

3-7 UNDERWATER WELDING ARCS ............................................................ 3-8

3-8 CONDITIONS ADVERSE TO UNDERWATER WELDING..................... 3-8

3-9 STRENGTH OF UNDERWATER FILLET WELDS ................................ 3-10

3-9.1 Parts of a Weld (Definitions) ....................................................................... 3-10

3-9.2 Fillet Weld ................................................................................................... 3-12

3-9.3 Trial Weld .................................................................................................... 3-12

3-10 SURFACE CLEANING.............................................................................. 3-12

3-11 JOINT FIT-UP............................................................................................. 3-13

3-12 UNDERWATER SHIELDED METAL-ARC WELDING TECHNIQUES ............................................................................................ 3-13

3-12.1 Welding Set-Up Procedures......................................................................... 3-13

3-12.2 Self-Consuming Technique ......................................................................... 3-14

3-12.3 Fillet Welding in the Horizontal Position (Self-Consuming Technique) .... 3-14

3-12.3.1 Fillet Welding in the Vertical Position ........................................................ 3-17

3-12.3.2 Fillet Welding in the Overhead Position...................................................... 3-17

3-12.3.3 Self-Consuming and Manipulative Techniques........................................... 3-20

3-12.3.4 Fillet Welding Where There is Poor Fit-Up ................................................ 3-20

3-12.4 Welding on Thin Plates................................................................................ 3-20

3-13 PROCEDURE FOR REPAIRING SMALL CRACKS............................... 3-22

3-13.1 Using a Rectangular Patch ........................................................................... 3-22

3-13.2 Using a Circular Patch ................................................................................. 3-22

3-14 POST-DIVE MAINTENANCE .................................................................. 3-25

CHAPTER (4).......... UNDERWATER ARC CUTTING AND WELDING EQUIPMENT

4-1 INTRODUCTION ......................................................................................... 4-1

4-2 EQUIPMENT USED FOR UNDERWATER ARC CUTTING AND WELDING ........................................................................................... 4-1

4-2.1 Oxygen-Arc and Shielded Metal-Arc Equipment ......................................... 4-1

4-2.2 Diving Equipment.......................................................................................... 4-1

4-2.2.1 Welding Shields............................................................................................. 4-1

4-2.3 Power Supply Requirements.......................................................................... 4-9

4-2.3.1 Power Converters........................................................................................... 4-9

4-2.3.2 Welding Generator, Pre-Setup Inspection ................................................... 4-11

4-2.3.3 Polarity......................................................................................................... 4-11

4-2.3.4 Polarity test .................................................................................................. 4-11

4-2.3.5 Tong Test Ammeter ..................................................................................... 4-13

4-2.3.6 Amperage and Voltage ................................................................................ 4-13

4-2.3.7 Diesel Driven Welding Generator Amperage and Voltage Settings ........... 4-15

4-2.4 Safety Switches............................................................................................ 4-16

4-2.5 Power Cables and Connectors ..................................................................... 4-16

4-2.6 Gas Manifolds.............................................................................................. 4-17

4-2.7 Underwater Oxygen-Arc Cutting Torches................................................... 4-17

4-3 EQUIPMENT FOR UNDERWATER SHIELDED METAL-ARC WELDING .................................................................................................. 4-19

4-3.1 Electrode Holders ....................................................................................... 4-19

4-4 WELDING ACCESSORIES ....................................................................... 4-20

Appendix Page

DOCUMENTATION MATRIX

A-1 PURPOSE..................................................................................................... A-1

A-2 REFERENCE DOCUMENTS...................................................................... A-1

METRIC CONVERSION FACTORS

English and Metric Equivalents .......................................................................................B-1

Weights ...................................................................................................................B-2

Measures .................................................................................................................B-2

Pressure or Stress (Force/Area) .......................................................................................B-3

Temperature Conversion..................................................................................................B-3

Metric Prefixes.................................................................................................................B-3

Multiplication Factors......................................................................................................B-3

C BIBLIOGRAPHY..........................................................................................................C-1< br> D SAFETY IN UNDERWATER CUTTING AND WELDING

D-1 PURPOSE..................................................................................................... D-1

D-2 GENERAL.................................................................................................... D-1

D-3 EXPLOSIVE GASES................................................................................... D-1

D-3.1 General Information...................................................................................... D-2

D-3.2 Specific Information ..................................................................................... D-2

D-4 ELECTRICITY UNDERWATER................................................................ D-4

D-5 GENERAL PRECAUTIONS FOR UNDERWATER CUTTING AND WELDING.................................................................................................... D-4

D-6 POWER SUPPLY......................................................................................... D-5

D-7 ELECTRODE HOLDERS AND CUTTING TORCHES ............................ D-6

D-8 POWER CABLES AND CONNECTORS................................................... D-7

D-9 SAFETY SWITCH....................................................................................... D-8

D-10 FIRE AND EXPLOSION PREVENTION................................................... D-9

D-10.1 Major Causes .............................................................................................. D-10

D-11 COMPRESSED GAS SUPPLIES .............................................................. D-10

D-11.1 Use, Handling and Storage of Compressed Gases...................................... D-10

D-11.1.1 The Never List ............................................................................................ D-10

D-11.1.2 The Always List.......................................................................................... D-11

D-11.1.3 General Oxygen Precautions ...................................................................... D-12

D-11.1.4 General MAPP Gas Precautions ................................................................. D-12

D-11.2 Additional Safety Precautions .................................................................... D-13

D-12 PERSONAL SAFETY IN DIVING ........................................................... D-14

D-12.1 Diving Dress ............................................................................................... D-14

D-13 CONCLUSION........................................................................................... D-14

E EXCEPTIONAL SITUATIONS

E-1 PURPOSE......................................................................................................E-1

E-1.1 Discussion......................................................................................................E-1

E-1.2 Authorization .................................................................................................E-1

E-2 UNDERWATER CUTTING EQUIPMENT.................................................E-1

v E-2.1 Arcwater Cutting............................................................................................E-1

E-2.2 Principles of Operation ..................................................................................E-2

E-2.3 Applications ...................................................................................................E-2

E-2.4 Necessary Equipment ....................................................................................E-2

E-2.4.1 Power .............................................................................................................E-2

E.2.4.2 Water..............................................................................................................E-2

E-2.4.3 Arcwater torch ...............................................................................................E-2

E-2.4.4 Electrodes.......................................................................................................E-2

E-2.5 Arcwater Electrode Cutting Technique .........................................................E-4

E-2.5.1 Underwater Preparations................................................................................E-4

E-2.5.1.1 Cutting ...........................................................................................................E-4

E-2.5.1.2 Gouging .........................................................................................................E-4

E-2.6 Material Consumption ...................................................................................E-5

E-2.7 Post-Dive Maintenance..................................................................................E-5

E-3 CUTTING UNDERWATER WITH THERMIC LANCE (BURN BARS)............................................................................................................E-5

E-3.1 Material Description ......................................................................................E-7

E-3.2 Required Equipment ......................................................................................E-8

E-3.3 Set Up Procedure ...........................................................................................E-8

E-3.4 Material Consumption ................................................................................ E-10

E-4 MAPP GAS CUTTING...............................................................................E-10

E-4.1 Principles of Operation ................................................................................E-10

E-4.2 Equipment and Material...............................................................................E-11

E-4.3 Protective Clothing ......................................................................................E-12

E-4.4 Cylinders and Regulators.............................................................................E-12

E-4.4.1 Purging the Hoses ........................................................................................E-12

E-4.5 Underwater MAPP Gas Cutting Torches.....................................................E-14

E-4.6 Igniting the Torch Above Water..................................................................E-16

E-4.6.1 Preparation ...................................................................................................E-16

E-4.6.2 Ignition.........................................................................................................E-16

E-4.7 Lowering the Ignited Torch .........................................................................E-18

E-4.8 Underwater Cutting......................................................................................E-18

E-4.8.1 Starting the Cut at the Edge of a Plate .........................................................E-18

E-4.8.2 Starting the Cut at the Central Portion of a Plate.........................................E-18

E-4.8.3 Advancing the Cut .......................................................................................E-21

E-5 UNDERWATER WELDING......................................................................E-22

E-5.1 Waterproofing Surface Electrodes...............................................................E-22

E-5.2 Preparation for Underwater Shielded Metal Arc Welding ..........................E-24

E-6 LOSS OF VOICE COMMUNICATIONS ..................................................E-26

E-7 FRICTION STUD WELDER......................................................................E-26

E-7.1 Principle of Operation..................................................................................E-26

E-7.2 Advantages...................................................................................................E-26

E-7.3 Equipment Requirements.............................................................................E-27

E-7.3.1 Equipment Details........................................................................................E-27

Glossary ............................................................................................. Glossary-1

Index ....................................................................................................... Index-1

LIST OF ILLUSTRATIONS

2-1 Underwater Oxygen-Arc Cutting Electrodes................................................................... 2-3

2-2 Underwater Oxygen-Arc Electrode Designs ................................................................... 2-4

2-3 Drag Techniques for Cutting Steel with Steel-Tubular Electrodes ............................... 2-12

2-4 Technique for Cutting Steel Less Than 1/4 Inch with Steel-Tubular Electrodes .......... 2-16

2-5 Technique for Piercing Holes in Steel Plate using the Oxy-Arc Process with Steel Tubular Electrodes................................................................................................ 2-17

2-6a Underwater Oxygen-Arc Cutting Torch Breakdown (Arcair)....................................... 2-19

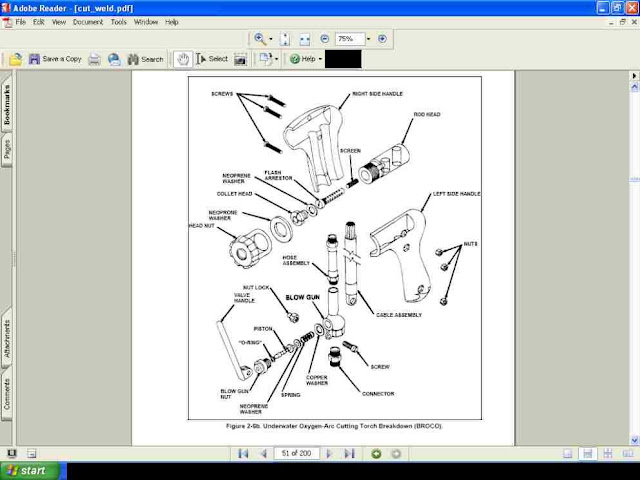

2-6b Underwater Oxygen-Arc Cutting Torch Breakdown (BROCO) ................................... 2-20

2-6c Underwater Oxygen-Arc Cutting Torch Breakdown (Craftsweld) ............................... 2-21

2-7 Technique for Cutting Steel Using Exothermic Electrode ............................................ 2-29

2-8 Seeler Kerie Cable Control Panel ................................................................................. 2-36

2-9 Typical Kerie Cable Set Up ........................................................................................... 2-38

2-10 Technique for Underwater Shielded Metal-Arc Cutting of Thick Plate and Round Stock................................................................................................................... 2-47

3-1 Test Specimen for Tee Fillet Weld .................................................................................. 3-5

3-2 The Underwater Welding Arc.......................................................................................... 3-9

3-3 Parts of a Weld............................................................................................................... 3-11

3-4 Self-Consuming Technique for Underwater Shielded Metal Arc Welding of Horizontal Fillet Welds ............................................................................................. 3-16

3-5 Self-Consuming Technique for Underwater Shielded Metal Arc Welding of Vertical Fillet Welds.................................................................................................. 3-18

3-6 Technique for Underwater Shielded Metal Arc Welding of Overhead Fillet Welds.................................................................................................................... 3-19

3-7 Feeding-In Technique for Underwater Shielded Metal Arc Welding of Fillet Welds in Wide-Gap Joints.................................................................................... 3-21

3-8 Repair Method for Cracks in Underwater Structures Using a Rectangular Patch......... 3-23

3-9 Repair Methods for Cracks in Underwater Structures Using a Circular Patch.............. 3-24

3-10 A Typical Underwater Welding Electrode Holder ........................................................ 3-26

4-1 Typical Arrangement of Underwater Arc Cutting Equipment ........................................ 4-2

4-2 MK12 SSDS Welding Shield .......................................................................................... 4-3

4-3 MK1, MOD 0 Mask and Lens Holder Assembly ............................................................ 4-4

4-4 Superlite-17B/NS Helmet and Lens Holder Assembly ................................................... 4-5

4-5 MK 12 Helmet Lens Holder Assembly with Parts Identification.................................... 4-6

4-6 Superlite-17B/NS Welding Lens Holder with Parts Identification ................................. 4-7

4-7 Typical Welding Generator and Power-Converter Control Panel ................................. 4-10

4-8 Equipment Arrangement for Welding and Cutting Straight Polarity ............................ 4-12

4-9 Tong Test Ammeter ....................................................................................................... 4-14v 4-10 Voltage Drop in Welding Cables................................................................................... 4-18

E-1 Arcwater Torch Assembly ...............................................................................................E-3

E-2 Thermic Lance Holder Assembly ....................................................................................E-9

E-3 Standard Thermic Lance Equipment Set Up ...................................................................E-9

E-4 Standard Surface Cutting Torch with Underwater Spacer Sleeve.................................E-15

E-5 Starting the Cut at the Edge of a Plate ...........................................................................E-19

E-6 Starting a Cut in the Central Portion of a Plate..............................................................E-20

E-7 Restarting the Cut ..........................................................................................................E-21

E-8 Friction Stud Welder......................................................................................................E-28

LIST OF TABLES

2-1 Cutting Amperage Requirements for Steel-Tubular Electrodes ...................................... 2-6

2-2 Oxygen Regulator Settings for Oxygen-Arc Cutting Electrodes (Hose Lengths 50 Foot and 200 Foot)...................................................................................................... 2-7

2-3 Material Consumption using Steel-Tubular Electrodes................................................. 2-10

2-4 Recommended Power Settings for Cable Length/Size for Ultrathermic Electrodes ....................................................................... 2-24

2-5 Exothermic Electrode Consumption Guide ................................................................... 2-26

2-6 Oxygen Regulator Settings for Kerie Cable Cutting ..................................................... 2-41

2-7 Kerie Cable Size/Metal to be cut ................................................................................... 2-42

2-8 Kerie Cable Oxygen and Cable Consumption Ratio ..................................................... 2-42

2-9 Material Requirements for Underwater Shielded Metal-Arc Cutting ........................... 2-45

3-1 Guide to Steels and Electrodes for Wet Welding ............................................................ 3-4

3-2 Electrodes for Underwater Shielded Metal Arc Welding................................................ 3-7

3-3 Recommended Amperage Settings for Wet Welding to Depths of 50 Feet .................... 3-7

4-1 Recommended Equipment for Underwater Arc Cutting and Welding............................ 4-8

4-2 Equipment Load-out for Wet Cutting/Welding Operations .......................................... 4-22

4-3 List of Manufacturers..................................................................................................... 4-26

4-4 Parts Information ........................................................................................................... 4-28

A-1 Salvage Documentation Matrix ...................................................................................... A-2

E-1 Arcwater Operating Data Cutting Carbon Steel ..............................................................E-6

E-2 Equipment and Material Requirements for Underwater MAPP Gas Cutting ........................................................................................................E-11

E-3 Regulator Gauge Settings ..............................................................................................E-13

E-4 Recommended Cutting Tip Sizes ..................................................................................E-14

E-5 Recommended Pressure Settings and Hose Size Selection Chart .................................E-17

E-6 Surface Welding Electrodes Suitable for Wet Welding ................................................E-23

E-7 Recommended Amperage Settings for Wet Welding to Depths of 50 FSW.................E-25

DON'T BE CONFUSED BY OTHER CD MANUALS!

LOW RESOLUTION Sample image From Adobe Acrobat Viewer (included on CD)

Actual CD images are higher resolution and clarity

.............................................................................

see ad description:

Payment and Shipping Details

Seller IP Address:

- United States

- United StatesCalifornia Sales Tax: Buyers located in the US State of California must pay an extra 9.00% sales tax as set by the seller. This comes out to be an extra $2.25 for this item based on the current price. This tax will be applied during checkout after a shipping address is provided.

Shipping services available:

| Shipping / Handling Cost | Cost For Each Additional Item | Service |

|---|---|---|

| $5.00 | $0.00 | Standard Shipping (1 to 5 business days) |

Payment methods accepted:

Check or Money Order

Check or Money Order

Return Policy:

Item must be returned within: 7 days - Buyer pays return shipping costs.

Refund will be given as: Money back

Return policy details: